Looking back at his past and Geuzestekerij De Cam, he said: “Some years ago, I sold all the barrels and equipment to Karel Goddeau, as it required a lot of work to run a lambic blendery. But I always have had a passion for spontaneous fermentation, for the geuze, lambic and kriek. When Timmermans offered me a chance to be a technical brewing consultant for them, I accepted.”

Van Herreweghen’s impressive brewing career dates back decades. He worked for Stella Artois before Interbrew (now AB-Inbev) took over, and later, for Palm. He has also consulted on a number of brewing projects in Europe. Even now, he still is a technical brewing consultant for Brouwerij De Ryck, Brasserie Trappistes Rochefort, and Brasserie du Val-Dieu.

Where he finds the time is anyone’s guess.

“My specialty is really hops, and I am involved with a spin-off of the University of Louvain-la-Nueve now,” he commented as we spoke.

A little about the history of the Timmermans brewery is in order. The brewery’s roots date to 1702, when Jacobus Walravens established a farm a few miles outside Brussels, with a café, orchard and malting house. It was called “Brasserie de la Taupe” which means “The Mole Brewery.” It is said that the brewing of geuze lambic began there the same year. The name “Brasserie de la Taupe” was kept until the early 1900’s, when it was changed to Brouwerij Timmermans. The name came from Frans Timmermans, who owned and ran the brewery in the late 19th century. Frans’ son-in-law, Paul Van Cutsem, made the name change to honor his father-in-law and the work he had done at the brewery.

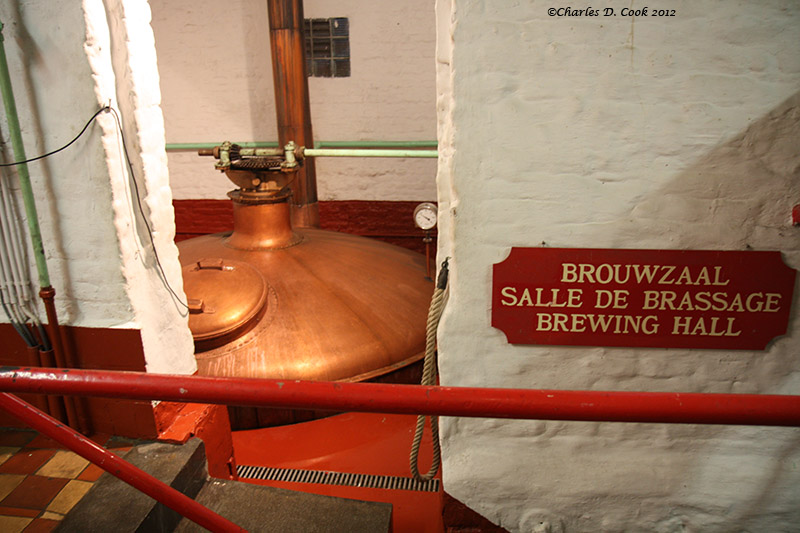

I’m happy to say that his descendants still help run Timmermans, including Frédéric Van Cutsem, the brewery Operations Manager. As we entered the brewery, he told me: “Let’s talk about the brewing process. Most of our brewhouse dates to 1946 or 1947. One of the copper kettles is a hot water tank, and we send hot water from a 118-meter (387-foot) deep artesian well, at 90 degrees Celsius, to the old open mash tun, which dates to 1920. We mix barley, wheat, and the hot water in over a 45-minute period, in two stages, at two different temperatures. We call this the ‘Madammen’ system here. The mash tun has copper discs that spin around to agitate and thicken the malts and wheat.”

Van Cutsem continued: “After the initial stage, the wort that has been extracted from the malts, grains and water is extracted, and heated in the boiling kettle. This heated wort is then pumped back to the mash tun, so more wort can be obtained form the remaining raw materials. When the mash and wort have reached 78 degrees Celsius, they are together pumped to the lauter tun (filtration tank, another copper vessel) where the filtering process begins. The filtration vessel was built by D’ Hondt, and dates to 1950. The filtering (lautering) process takes about two and a half hours, and is very meticulous.”

Leave a Reply